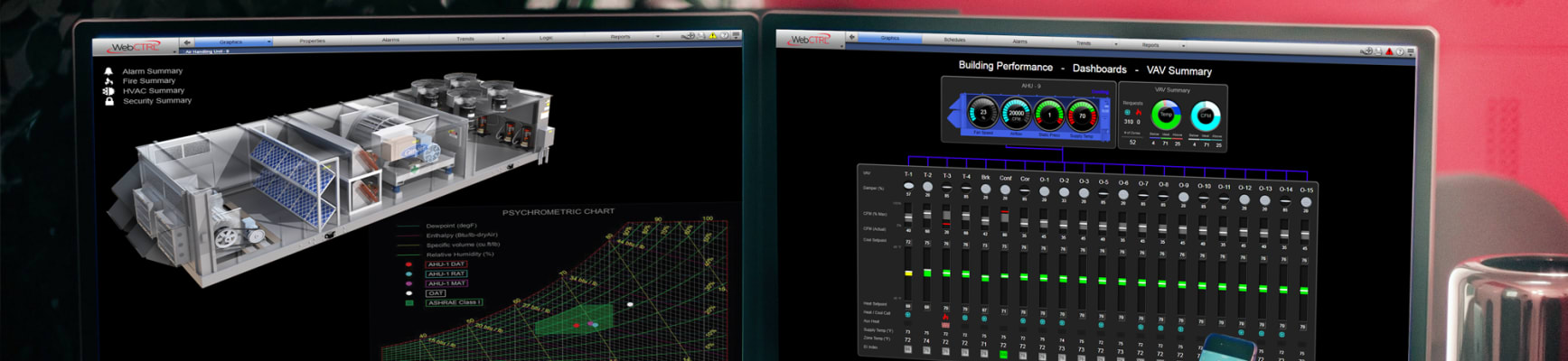

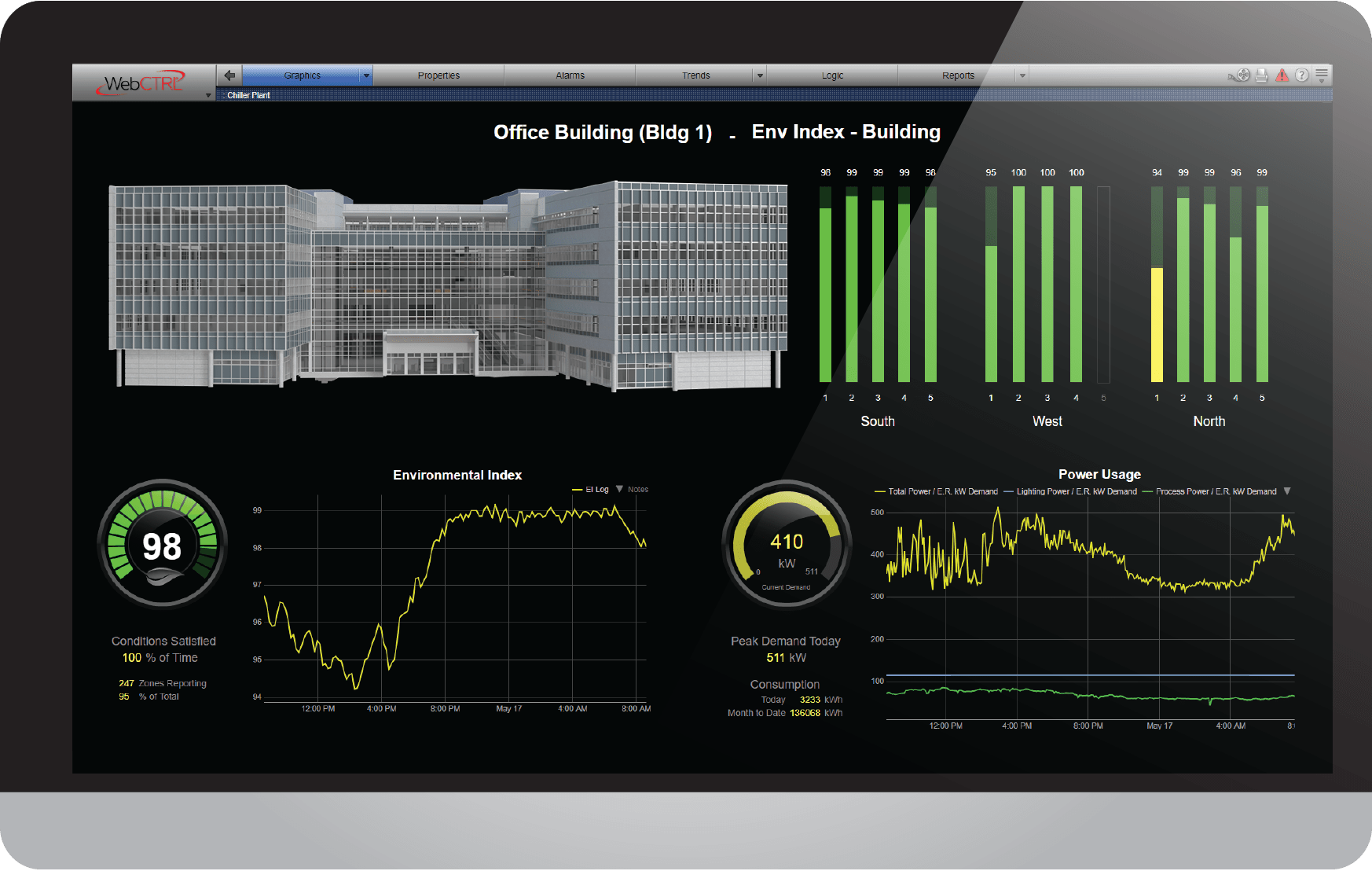

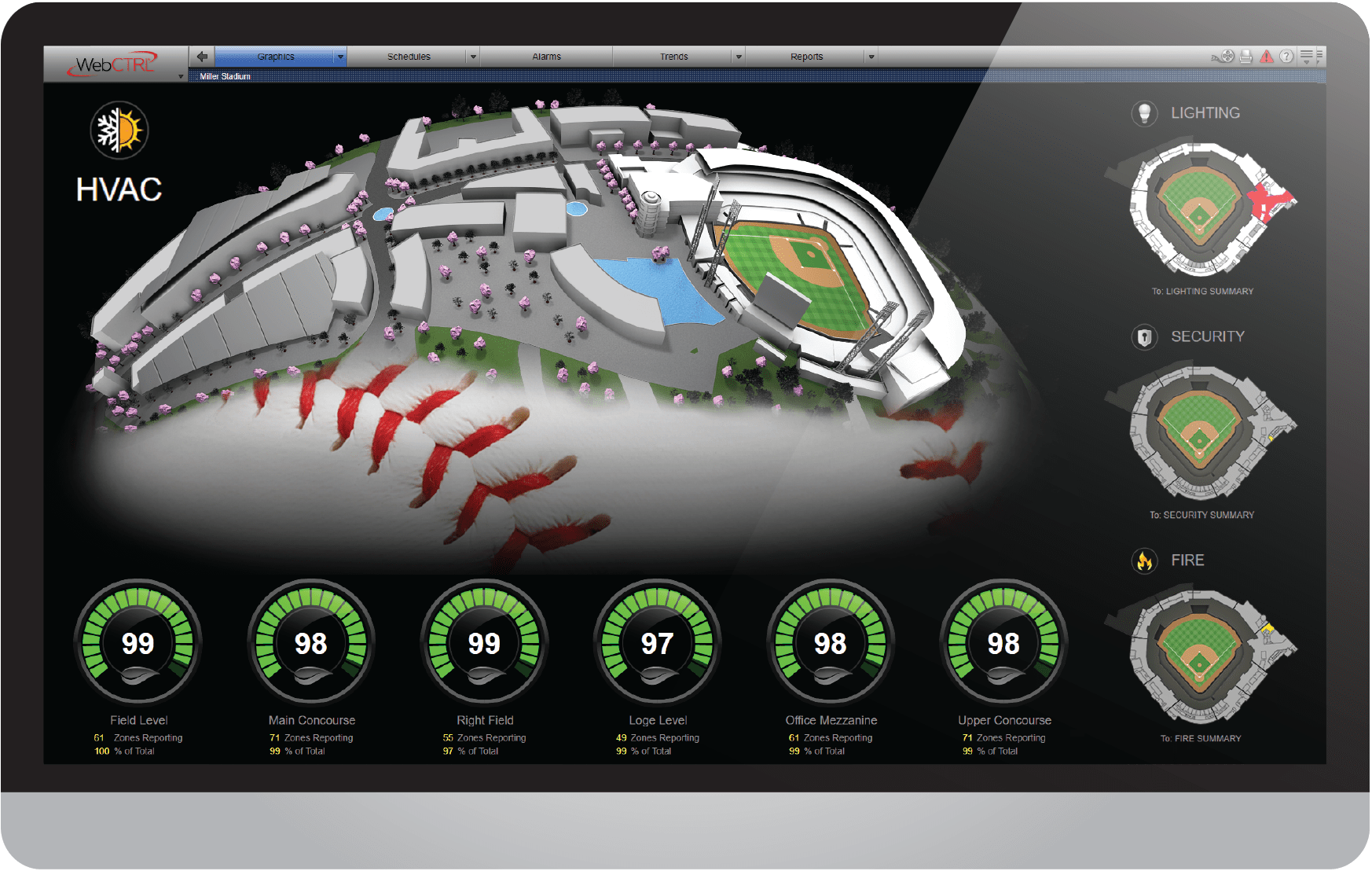

WebCTRL’s web-based software is the “single pane of glass” that allows facilities staff to manage all of their building systems, including heating, cooling, ventilation, lighting, safety, security, and much more - from anywhere at any time.

Learn more about the success we've had partnering with customers to improve the operation of their intelligent buildings.