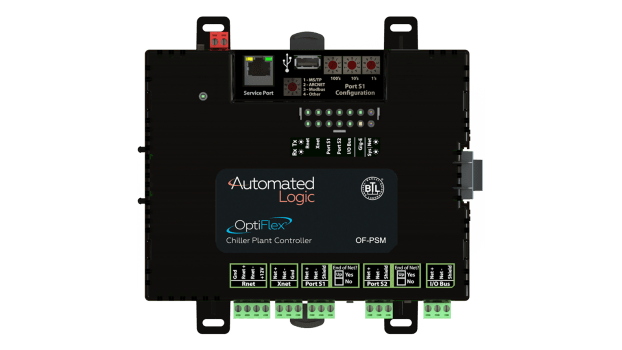

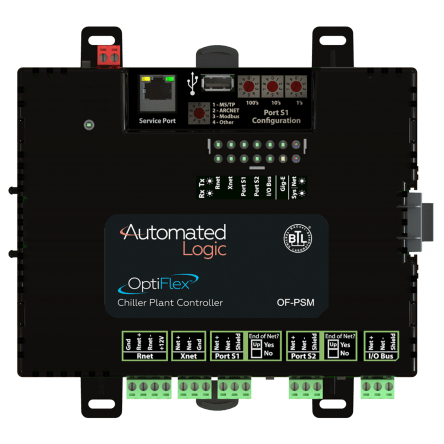

PlantCTRL® Chiller Plant Manager - OF-PSM

The OptiFlex PlantCTRL controller is a factory-engineered, cutting-edge control solution that offers algorithms designed to provide optimized control over all aspects of a chiller plant, coordinating the control of chillers, pumps and towers into a finely tuned, cohesive system. The solution consists of a dedicated chiller plant controller, I/O expanders, and a library of factory-engineered control programs that are specifically designed to cover the most common chiller plant configurations.

Application Features

- Responds to the building load, automatically starting, staging and stopping the plant, resetting the chilled water supply temperature, and matching the tonnage produced to the tonnage required by the building

- Proven, reliable, factory-engineered and supported control algorithms for plant management

- Designed to reduce engineering and commissioning labor

- Supports advanced algorithms, optimizations, diagnostics, and analytics add-ons

- Supports optional flow meter inputs for tonnage calculations

- Graphically programmed with self-documenting control sequences and a live view of all sequence components

- Supports Equipment Touch, providing local access to the system

- Supports full integration with chiller plant equipment via BACnet or Modbus® protocols

Hardware Features

- Includes four energy dashboards: water-cooled plant home screen, air-cooled plant home screen, chilled water system detail screen, condensed water system detail screen

- Native BACnet communications to field devices over TCP/IP, Ethernet, or BACnet MS/TP networks

- Supports MEX and FIO expanders panel configuration or remotely mounted for flexible modernization and scalable solutions (180 I/O points total)

- Fully graphically programmable, with full communications with other Automated Logic controllers

- Universal inputs and outputs, with HOA override switches and potentiometer adjustment available on all outputs

- Battery-backed real-time clock provides true standalone capability allowing complete recovery from power outages

- Responds to the building load, automatically starting, staging and stopping the plant, resetting the chilled water supply temperature, and matching the tonnage produced to the tonnage required by the building

- Proven, reliable, factory-engineered and supported control algorithms for plant management

- Designed to reduce engineering and commissioning labor

- Supports advanced algorithms, optimizations, diagnostics, and analytics add-ons

- Supports optional flow meter inputs for tonnage calculations

- Graphically programmed with self-documenting control sequences and a live view of all sequence components

- Supports Equipment Touch, providing local access to the system

- Supports full integration with chiller plant equipment via BACnet or Modbus® protocols

- Includes four energy dashboards: water-cooled plant home screen, air-cooled plant home screen, chilled water system detail screen, condensed water system detail screen

- Native BACnet communications to field devices over TCP/IP, Ethernet, or BACnet MS/TP networks

- Supports MEX and FIO expanders panel configuration or remotely mounted for flexible modernization and scalable solutions (180 I/O points total)

- Fully graphically programmable, with full communications with other Automated Logic controllers

- Universal inputs and outputs, with HOA override switches and potentiometer adjustment available on all outputs

- Battery-backed real-time clock provides true standalone capability allowing complete recovery from power outages